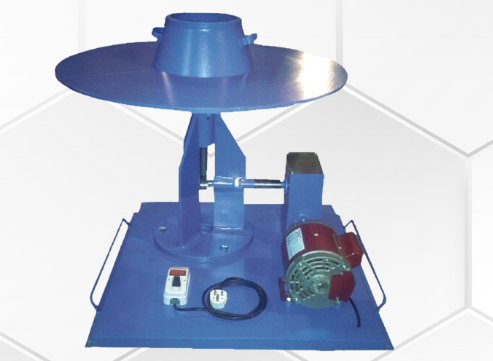

FLOW TABLE AEC – 406-01

FLOW TABLE

Model No : AEC – 406-01

Standards As per : IS 5512 – 1983

Flow Table Motorized Cement : ( AEC - 40601)

A Motorized Flow Table is a laboratory apparatus used to determine the consistency and workability of cement mortars and similar materials.

-

- Featuring a motorized lifting and dropping mechanism, it ensures consistent, repeatable jolting action during flow measurement.

- Assess the flowability (plasticity) of cement mortar.

- Deliver standardized and repeatable test results through automation.

- Ensure precision in tests without manual variability.

- Evaluate water content and admixtures' effects on mortar flow.

- Used in quality control labs, R&D institutions, and construction material testing.

- Cement mortar sample is placed in a standard conical flow mould on the flow table.

- After tamping, the mould is lifted vertically.

- Motor lifts and drops the table automatically from a fixed height (12.5mm), 25 times in 15 seconds.

- Post-drop, the mortar's spread diameter is measured in two directions.

- The average flow diameter reflects the consistency and workability.

- Motorized Operation: Eliminates manual error by automating drop cycles.

- Accurate Timer Control: In-built preset timer ensures precise test cycles.

- Compact & Rigid Design: Built to withstand vibrations and frequent lab

use. - Corrosion-Resistant Table: Polished stainless steel ensures easy cleaning and long life.

- Smooth & Precise Movement: Drop height and frequency consistent across cycles.

- Plug-and-Play: Operates with standard 220V power supply with overload protection.

- Compliance Certified: Adheres to IS/ASTM/BIS standards for cement mortar flow tests.